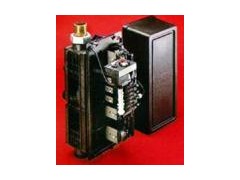

The 172 Series 2-inch side-mounted valve can be used with single-, dual- and triple-tank systems. Construction of lightweight, corrosion-proof, glass-filled Noryl* maximizes chemical resistance and durability. A static-seal flapper design offers the most reliable method for sealing a port. And the 172 valve' s pressurized brine system doesn' t need to rely on a time cycle for operation. Quick-connect fittings ensure easy installation on a variety of tanks.

Features and Operation

The GE Osmonics Autotrol 172 Series control valve is a corrosion-resistant, 2-inch composite water softener or filter valve.

The valve is made of glass-reinforced Noryl, a structural plastic designed to stand up to the rigors of water softener or filter service. The corrosion-proof materials make this an ideal valve for use with the variety of chemicals used in water treatment regeneration.

The 172 valve features a static sealing flapper valve design which minimizes problems with debris in the water. The flappers are driven by hydraulic plungers on rolling diaphragms which provide smooth, quiet operation. The diaphragms are controlled by a pilot-valve assembly.

Control options include the Autotrol 440 six- or seven-day timer. The 450 impulse timer can also be used. The 172 valve requires a three-minute start signal which can be provided by the Autotrol 480QC demand regeneration control.

The small timer used to operate the pilot valves allows the use of one synchronous motor. This motor operates both the program timer and the pilot valve control cam.

Backwash timers are adjustable from three to15 minutes in three-minute steps. Brine rinse control time is adjustable from 22 to 62 minutes in four-minute steps.

The timer allows an installer or service person to manually index the cam, testing any one of the regeneration positions. This facilitates service and setup. The control is a five-cycle design. A separate pilot is provided to offer a hydraulic signal during regeneration. This allows for the easy use of service, bypass and lockout diaphragm valves.

The 172 valve is designed with quick disconnect fittings so that it can be set up with 2-inch NPT or BSPT brass adapters. Two inch PVC socket weld fittings are also available.

The 172 Series valve has been designed to provide reliable performance as a softener or filter control valve. The use of plastic materials allows the user greater versatility in the use of water conditioning regenerants. For softener applications, the 172 valve has the following cycles:

* Backwash loosens, cleans and stratifies the ion exchange resin.

* Brine is introduced in a downflow direction.

* Rinse washes the excess brine and hardness ions out of the resin.

* Pressurize packs the resin bed.

* Brine Refill and Purge refills the brine tank and removes the last traces of excess brine.

* Service provides continuous supply of soft water.